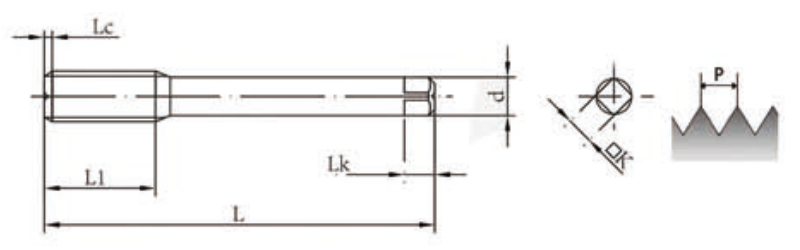

HSSE Forming Thread Taps (TICN Coated)

| Model | L | L1 | d | k |

|---|---|---|---|---|

| M1.0x0.25 RH4 | 32.5 | 3.5 | 3 | 2.5x3 |

| M1.0x0.25 RH4 | 32.5 | 4.5 | 3 | 2.5x3 |

| M1.2x0.25 RH4 | 32.5 | 3.5 | 3 | 2.5x3 |

| M1.2x0.25 RH4 | 32.5 | 4.5 | 3 | 2.5x3 |

| M1.4x0.3 RH4 | 37 | 6.5 | 3 | 2.5x3 |

| M1.6x0.35 RH5 | 37 | 8 | 3 | 2.5x3 |

| M1.7x0.35 RH4 | 37 | 8 | 3 | 2.5x3 |

| M1.8x0.35 RH4 | 37 | 8 | 3 | 2.5x3 |

| M2x0.4 RH5 | 45 | 10 | 3 | 2.5x3 |

| M2.3x0.4 RH5 | 45 | 10 | 3 | 2.5x3 |

| M2.5x0.45 RH5 | 45 | 13 | 3 | 2.5x3 |

| M2.6x0.45 RH5 | 45 | 13 | 3 | 2.5x3 |

| M3x0.5 RH7 | 50 | 16 | 4 | 3.2x6 |

| M3.5x0.6 RH7 | 50 | 16 | 4 | 3.2x6 |

| M4x0.7 RH7 | 57 | 18 | 5 | 4x7 |

| M5x0.8 RH7 | 66 | 20 | 5.5 | 4.5x7 |

| M6x1.0 RH7 | 62 | 24 | 6 | 4.5x7 |

| M7x1.0 RH7 | 70 | 13 | 6.2 | 5x8 |

| M8x1.0 RH7 | 70 | 13 | 6.2 | 5x8 |

| M8x1.25 RH7 | 70 | 13 | 6.2 | 5x8 |

| M10x1.0 RH7 | 75 | 13 | 7 | 5.5x8 |

| M10x1.25 RH7 | 75 | 13 | 7 | 5.5x8 |

| M10x1.5 RH7 | 75 | 15 | 7 | 5.5x8 |

| M12x1.0 RH7 | 82 | 13 | 8.5 | 6.5x9 |

| M12x1.25 RH8 | 82 | 13 | 8.5 | 6.5x9 |

| M12x1.5 RH8 | 82 | 17 | 8.5 | 6.5x9 |

| M12x1.75 RH8 | 82 | 17 | 8.5 | 6.5 |

| M14x1.0 RH7 | 88 | 13 | 10.5 | 8x11 |

| M14x1.25 RH7 | 88 | 13 | 10.5 | 8x11 |

| M14x1.5 RH8 | 88 | 20 | 10.5 | 8x11 |

| M14x2.0 RH8 | 88 | 20 | 12.5 | 10x13 |

| M16x1.0 RH8 | 95 | 13 | 12.5 | 10x11 |

| M16x1.25 RH8 | 95 | 13 | 12.5 | 10x13 |

| M16x1.5 RH8 | 95 | 20 | 12.5 | 10x13 |

| M16x2.0 RH9 | 95 | 20 | 12.5 | 10x13 |

HSSE Drilling Size of Forming Taps(Metric)

| Parts # | For JIS Class 1 drill hole dia | For JIS Class 1 drill hole dia | For JIS Class 2 drill hole dia | For JIS Class 2 drill hole dia |

| Metric Screw Thread (Nu-Roll Tap)(NRT) | RH Precision | Min-Max Thread Grip Ratio% | RH Precision | Min-Max Thread Grip Ratio% |

| M1x0.25 | 2 | 0.87~0.89(100~85) | 4 | 0.90~0.92(100~80) |

| M1.2x0.25 | 2 | 1.07~1.09(100~85) | 4 | 1.10~1.12 (100~80) |

| M1.4x0.3 | 2 | 1.244~1.263(100~85) | 4 | 1.270~1.294(100~80) |

| M1.6x0.35 | 2 | 1.40~1.44(100~80) | 4 | 1.44~1.48(100~75) |

| M1.7x0.35 | 2 | 1.51~1.54(100~80) | 4 | 1.54~1.58(100~75) |

| M2x0.4 | 2 | 1.78~1.82(100~80) | 4 | 1.81 ~1.85(100~75) |

| M2.3x0.4 | 2 | 2.08~2.12(100~80) | 4 | 2.11~2.15(100~75) |

| M2.5x0.45 | 2 | 2.25~2.29(100~80) | 4 | 228~2.33(100~75) |

| M2.6x0.45 | 2 | 2.35~2.39(100~80) | 4 | 2.38~2.43(100~75) |

| M3x0.5 | 3 | 2.74~2.78 (100~80) | 5 | 2.76~2.81(100~75) |

| M3.5x0.6 | 3 | 3.18~3.21(100~85) | 5 | 3.20~3.26(100~75) |

| M4x0.7 | 4 | 3.63~3.67(100~85) | 6 | 3.65~3.70(100~85) |

| M5x0.8 | 4 | 4.57~4.62(100~85) | 6 | 4.59 ~4.66 (100~80) |

| M6x1.0 | 4 | 5.45~5.51(100~85) | 7 | 5.48~5.57 (100~80) |

| M7x1.0 | 4 | 6.45~6.51(100~85) | 7 | 6.48~6.57(100~80) |

| M8x1.25 | 5 | 7.31~7.38(100~85) | 7 | 7.34~7.41(100~85) |

| M10x1.5 | 5 | 9.16~9.22(100~90) | 7 | 9.18~9.28(100~85) |

| M12x1.75 | 5 | 11.01~11.08(100~90) | 8 | 11.05~11.15(100~85) |

| M14x2.0 | 6 | 12.83~12.95(100~90) | 10 | 12.92~13.04(100~85) |

| M16x2.0 | 6 | 14.87~14.95(100~90) | 10 | 14.92~15.04(100~85) |

At Buyustools, we take pride in offering a comprehensive range of high-quality thread taps designed to meet the demands of precision machining. Whether you are a professional machinist or a seasoned DIY enthusiast, our premium thread taps are engineered to deliver exceptional performance, durability, and reliability.

Key Features

Durable Construction

Crafted from High-Speed Steel with Cobalt (HSSE) for exceptional durability and resistance to wear and tear.

Wide Material Compatibility

Suitable for use with various materials, including steel, aluminum, brass, and more.

Enhanced Wear Resistance

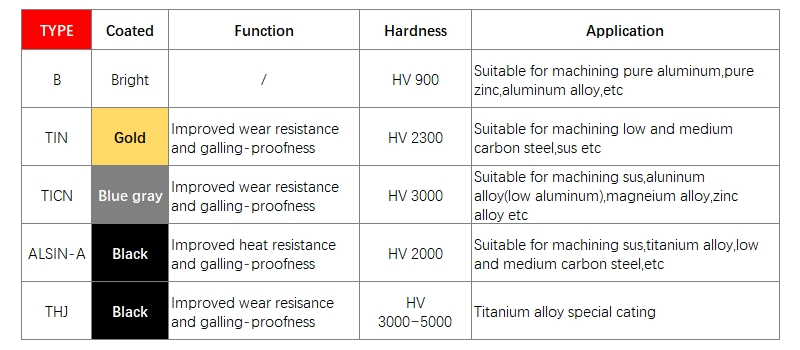

Coated thread taps are treated with special coatings (e.g., TiN, TiCN, TiAlN) that significantly improve wear resistance.

Discover Precision Thread Taps for Your Needs

iCarbide HSSE (High-Speed Steel with Cobalt) Forming Thread Taps, TICN Coated, are precision-engineered tools designed for creating strong and accurate threads in various materials. These taps are ideal for applications where thread precision and durability are crucial.