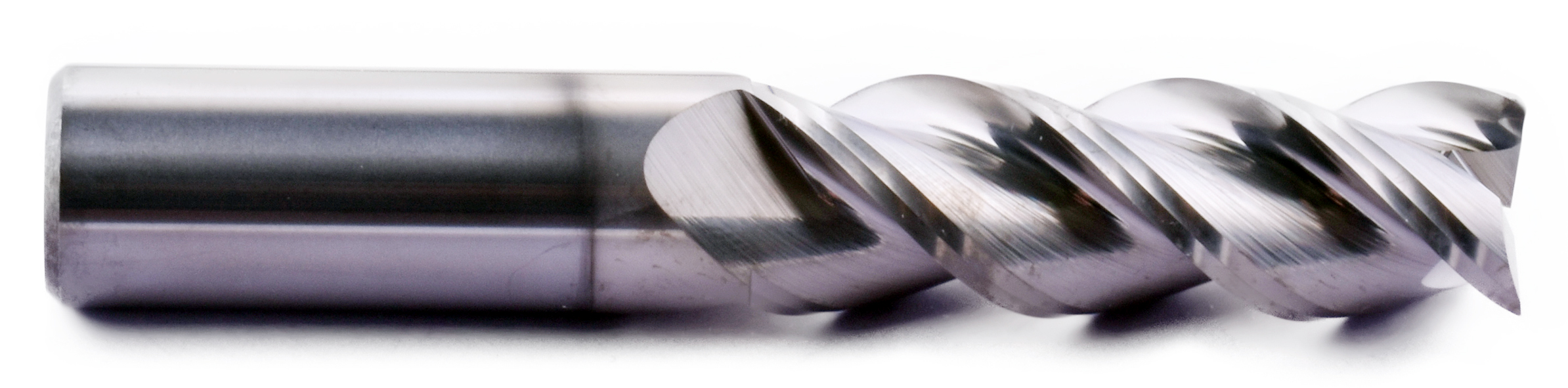

| ORDER NO | ICB1118 | MATERIAL | MIRCO-TUNGSTEN |

| CUTTING TYPE | SQUARE END MILL | CUTTING DIAMETER | 1/8 |

| NUMBER OF FLUTE3 | 3 | FLUTE LENGTH | 3/8 |

| FINISHING COATE | ACC ALUSPEED | SHANK DIAMETER | 1/8 |

| HELIX ANGLE45 | 45 | OVER LENGTH | 1-1/2 |

| SHAPE | FLAT SIDE MILL | SHANK TYPE | ROUND |

| BRAND | MADE IN TAIWAN | CUTTING TYPE | SINGLE END |

1/8×1-1/2 ” 3FLUTE CARBIDE END MILL CC ALU SPEED COATED FOR ALUMINUM

The sharpness of the knife can be maintained after coating

High toughness and high rigidity

Self-lubricating function: a low affinity for cold welding, cutting edge

The surface is extremely smooth, and the chip flutes can be removed without chips during milling and drilling

Excellent smoothness on the guide vane and excellent alignment of the machined holes

Very suitable for processing aluminum, copper, titanium alloys and ALSi alloys with a silicon content of less than 10% (for products with higher silicon content, we recommend using diamond coating)

Cutting Condition

| Diameter | VC(m/min) | AP(mm) | AE(mm) | FEED (mm/min) | RPM/MIN |

|---|---|---|---|---|---|

| 1/8 | 150 | 0.15 | 0.15 | 2000 | 24000 |

| 3/16 | 226 | 0.17 | 0.17 | 2500 | 18000 |

| 1/4 | 350 | 0.2 | 0.2 | 2800 | 15000 |

| 3/8 | 420 | 0.25 | 0.25 | 3000 | 13000 |

| 1/2 | 450 | 0.3 | 0.3 | 3500 | 8000 |

Tungsten Material Tungsten (WC+Co) hard alloy (YG)

It has high toughness of flexural strength and good thermal conductivity, but has a poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3 and YG6, and its strength and toughness are slightly worse. It is suitable for processing hard cast iron and austenitic stainless steel. , Heat-resistant alloy, hard bronze, etc.

Related Products

| Order No | D1(MM) | L1(mm) | D(mm) | L(mm) | COATED | TOOTH |

|---|---|---|---|---|---|---|

| ICB1118 | 1/8 | 1/2 | 1/8 | 1-1/2 | ACC ALU | 3 |

| ICB1119 | 3/16 | 5/8 | 3/16 | 2 | ACC ALU | 3 |

| ICB1120 | 1/4 | 3/4 | 1/4 | 2-1/2 | ACC ALU | 3 |

| ICB1121 | 3/8 | 1 | 3/8 | 2-1/2 | ACC ALU | 3 |

| ICB1122 | 1/2 | 1-1/2 | 1/2 | 4 | ACC ALU | 3 |

Ionbond provides thin-film coating services and operates, includes PVD, PACVD, CVD, CVA, and CVI technologies,

including a broad range of DLC coatings. Please contact us for further information.

We look forward to serving you.

Cutting Tested

| Material :AlSi1MgMn | Vc=1200m/min(3936,96sf/min) |

| Cutter Diameter 3/8″ | n=38200rev/min |

| Cutting Type: CNC Milling | ft=0,084/t(0,0033″/t) |

| Cutting with coolant | Result: no damage |